The Basic of Frozen Surimi

Contents

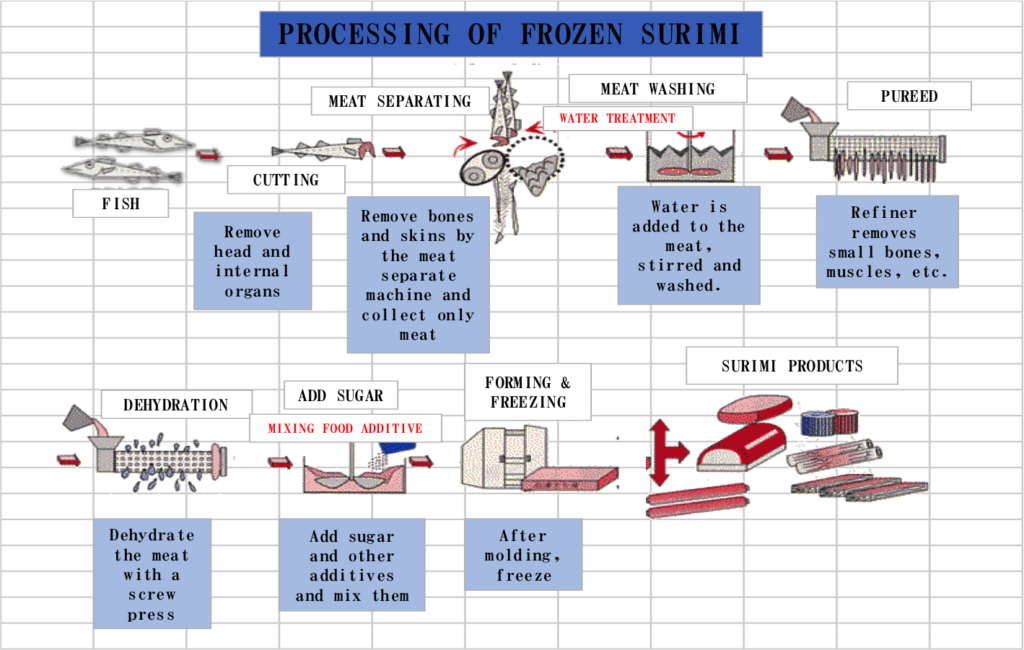

Manufacturing process of frozen surimi

Manufacturing process of frozen surimi

- Removal of head, visceral parts,

- Soaking in water,

- Removal of skin, bone and collect fish meat,

- Add water and wash thoroughly,

- Removal of waste, small bones through refiner

- Removal of excess water with screw pressor

- Mix with additive(add sugar),then surimi completed

- Forming and freezing(keep it freezing rapidly after the formation) Frozen surimi is completed.

Birth process of frozen surimi

The birth process of frozen surimi is as follows.

The background is

1) an increase in the catch of walleye pollock

2) an increase in the demand for fish sausage and kamaboko.

At the same time, the development of frozen surimi made from walleye pollock was carried out.

The problem with the initial development was that Alaska pollack meat was easily frozen and denatured (sponged by freezing).

1) Thorough washing of meat

2) Addition of sugars such as sugar

We were able to suppress freezing denaturation through technological development(1960).

Therefore, long-term storage and mass processing became possible, which had an effect on the stable supply of raw materials for paste products and the development of walleye pollock.

Manufacturing process of frozen surimi on board

1.Unloading process

After catching the fish, we have put them into the tank and sorted out after unloading them in the factory.

Then we use fresh fish that have passed in inspection as raw materials for surimi.

2.Fish meat separating process

After removing head, visceral parts, bones and wastes,fresh lean meat from fish has been separated.

3.Soaking in water

After the soaking process in water tank,blood,water soluble protein , fat ,mineral , etc. are removed from the lean meat of fish. Soaking surimi into water is affective way of deterring a breach-out process of the color.

4.Draining process

After the soaking, water is removed unnecessary elements (water soluble protein, fat, mineral, etc)

in water and help to keep fish meat soft in the next process of refiner.

5.Refiner process

We have eliminated fish skin, bones, blood, etc. by using refiner. Depending on the quality of fish meat,we adjust rotor’s rpm, the gap between rotor bladesand the plate, size of the mesh, etc.

Appropriate operation of refiner could greatly affect the quality of surimi.

6.Processing by screw pressor

After the refiner process, water is removed from the fish meat by screw pressor. Through this process, water value in the fish meat returns to the original value.

7.Processing by silent cutter

After adding sugar, sorbitol to the fish meat, we have mixed it evenly by silent cutter. In the process, additives show the deterrent effect of freezing denaturation and fish meat is completed.

8.Filling and measuring process

Completed fish meat is filled into 10Kg of poly-bag by filling machine and then put them into freezing pan.

After this process, it has been treated with rapid freezing system and transferred to the box. Products are thoroughly checked by metal detector and keep them into storage for delivery.

Differences in general properties of frozen surimi on board and on land

on board

- The freshness is good, and it is processed about 6 hours after death.

- Protein denaturation of fish is not so advanced.

- When prepared in Kamaboko, it sits well and forms a strong gel.

on land

- Some of them are inferior in freshness and are processed after 10 days after death at the longest.

- Often used for fried foods and chikuwa products.

- Protein denaturation has already occurred in the raw fish. So don’t setting.

- Used in products where impurities such as black skin are inconspicuous.

Frozen surimi protein

The category of fish meat protein and its feature

1.Sarcroplasmic protein

As a water soluble globular protein, it is called zymoprotein or chromoprotein.

It is eliminated when soaked in water.

2.Myofibrillar protein

It is insoluble in water, but it dissolves in saline solution. The most important thing is that it has myosin and actin which is related to elasticity of the products.

3.Extracellular

It is insoluble in water, neutral salt solution, dilute acid, dilute alkali.

It contains elastin, collagen which helps to form vascular tissue or connective tissue in muscle.

Water exposure during the frozen surimi manufacturing process

The purpose is to remove the sarcoplasmic protein by exposing it to water.

However, at the same time, the umami component is lost.

So seasoning technology is required due to lack of fish flavor Becomes important.

A mixture of myofibrillar protein and extracellular protein is a surimi protein.

To make Kamaboko, which forms supple and smooth elasticity, high-grade surimi containing a large amount of myofibrillar protein is used.

Lower surimi, which has a high proportion of extracellular protein, tends to be less smooth.

Additives to be added to frozen surimi

The purpose is to prevent freeze denaturation.

Prevents the release of free free water around the protein and bound water bound to the protein.

Usually, 4.0% sugar, 5.0% sorbitol and 0.2-0.3% phosphate are added.

Freezing of frozen surimi

It is important to freeze as soon as possible with a contact freezer to reduce ice crystals.

It also has the meaning of minimizing the biochemical changes (decrease in freshness) of proteins.

It should be stored at -25℃ or lower.

General properties of frozen surimi

The quality of kamaboko depends on the quality of the frozen surimi that is the raw material.

The quality of frozen surimi is affected by the freshness of the raw fish.

The fresher the salt, the greater the effect of dissolving salt. You can make high quality kamaboko.

Quality judgment of frozen surimi

The biggest factor that influences the quality of Kamaboko is the quality of the main raw material, surimi.

The quality standards and labeling of surimi are different for each surimi manufacturer, and there is no universal standard.

From the standpoint of the user, the actual quality at the time of use must be judged and a certain product cannot be manufactured.

The point of surimi judgment is to decide the check items and always make the inspection judgment by the same method according to a certain manual.

Accurate judgment is possible by accumulating data.

Offshore and land-based fish, and other fish species such as Alaska pollack and Itoyori, but basically the same method can be used for determination.

Items for quality judgment of frozen surimi

Standards for frozen surimi

Raw material for frozen surimi

Precautions when using frozen surimi

1.Accurately judge the standard shown in the display standard and the quality of the actual surimi.

2.The fact is that some surimi with high-grade display has only high-grade non-standard quality such as intermediate jelly strength.

3.Since frozen surimi is the main raw material for paste products, it can be said that what is important when making paste products is not the technology for processing the paste, but the technology for correctly evaluating the quality of the paste itself.

4.Anyone can make a good product by making a surimi product using high quality surimi. On the other hand, if you use poor quality surimi, no matter who does it, you will end up with a poor quality product.

This is the advantage and disadvantage of frozen surimi.

It is important to be able to accurately grasp the quality of the surimi (gel forming ability) at the time of purchase.